Flowcoach

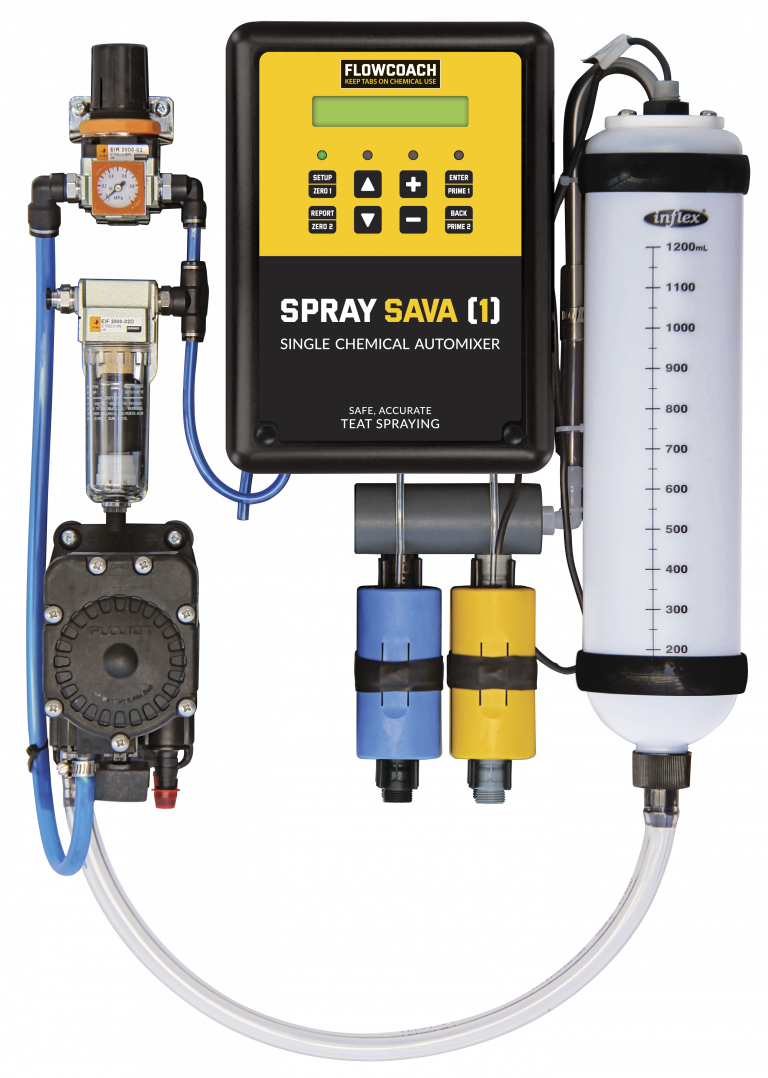

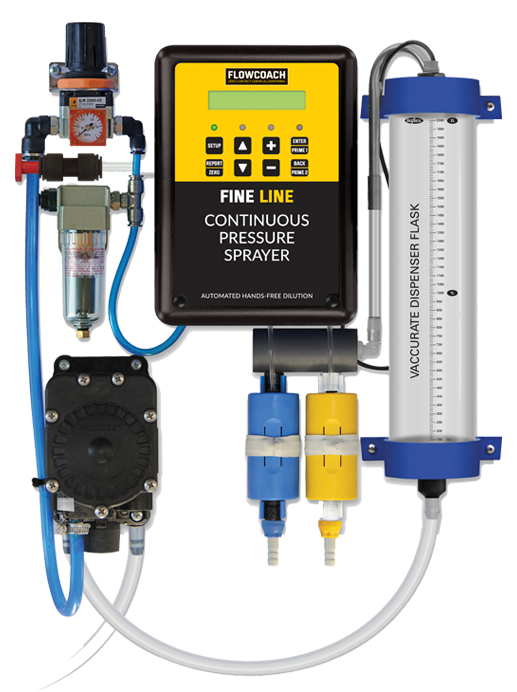

PRODUCTS

Flowcoach products dispense micro volumes of concentrated chemicals or liquid additives direct from product shipping containers. Doses measured as a volumetric ‘shot’ automatically mixed with water to create precision dilutions, mixes, or sprays.